.

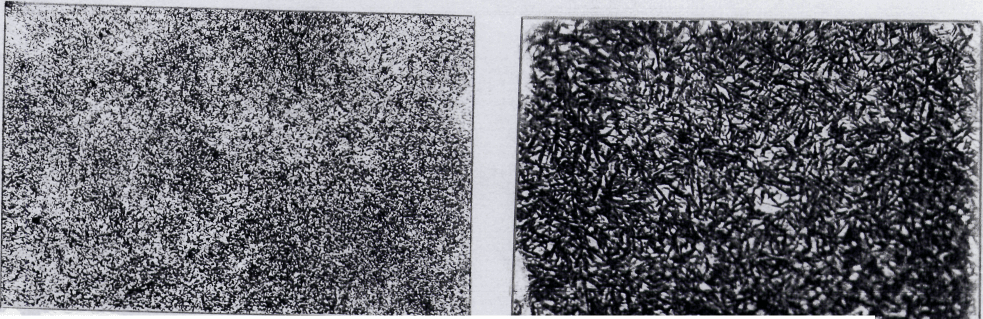

Damascus steel is a composite carbon steel with a visible pattern that has been made by mankind for several millennia. One of the most common and at the same time the easiest to make types of such metal is the so-called “wild damask”. It is made by welding a package of strips from several grades of steel, with multiple bending and forging. The package is heated in a crucible and added on top of various materials (so-called flux), which fuses with the scale formed on the surface of the plates, cleans from it welded surfaces. Dissolving scale, flux simultaneously forms a liquid slag, protecting the surface of the metal from further oxidation. Package with liquid slag heated to white heat and forged. After the first welding of the package it is uncovered on a strip and cut into several pieces, which are again stacked and made a second welding. Welding can be repeated many times until the desired steel characteristics appear. As a result, the layers of metal are mixed randomly and a pattern is formed on the surface of the bar. The appearance of the pattern depends on the number of layers and the grades of steel used. Light lines in the steel pattern give a high level of chromium or nickel. Dark lines show the use of carbon steels.

There are a number of standard problems associated with creating damascus. The main quality of Damascus steel is considered to be the alternating layers of metal with high carbon content, which give an aggressive cut, and low carbon content, which give it strength. However, during forge welding of layers with different carbon content, carbon diffusion occurs and they mix with each other. This degrades the cutting properties of the high-carbon components of the package by depleting the amount of carbon, and the large number of welds can reduce the strength of the blade. Moreover, the amount of carbon can burn out to appreciable amounts during the welding process, weakening the wear resistance of the steel. As a result, the consumer cannot often predict the properties of the resulting blade. It is widely known that damask can for no apparent reason simply stop cutting even on a well-sharpened knife, it can flake out, become very brittle. The fight against these drawbacks and the development of powder steel production technologies pushed knife makers first to artisanal experiments with powder steels, and then to the application of complex high-tech solutions.

The key role in the development of modern damask manufacturing technologies was played by the appearance of new technological equipment in the knife industry. Industrial forging presses, electric arc furnaces with controlled atmosphere, etc. began to be used for manufacturing of knife steel. In particular, specialized vacuum rolling mills, expanded productivity and allowed the development of industrial production of damask on the basis of the latest technologies of powder metallurgy.

The use of vacuum technology for the production of Damascus steel, allows the use of both metal bars and powder method as raw materials.

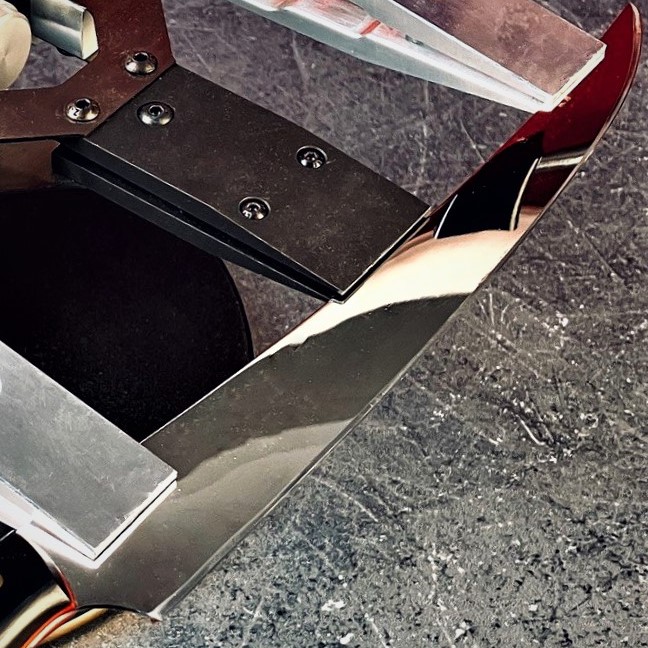

.

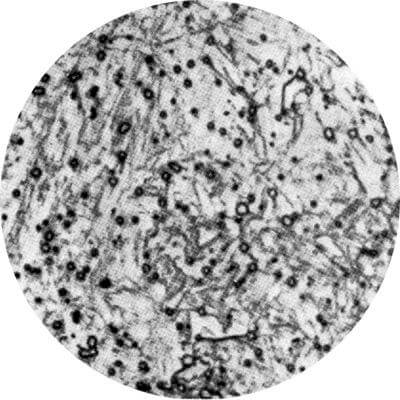

The main advantage of the vacuum method for welding plates of traditional damask is the absence of oxidation of metal during heating. This makes it possible to pre-weld high-alloyed, including stainless steels without flux. Connected ground plates are welded by diffusion welding in a vacuum chamber under a press. The package welded in this way is expanded into plates, which are again ground and welded until the required number of layers is obtained. This method can be used to produce damask from stainless and alloy steels. An excellent method of welding high-alloy steels is also rolling a package of ground or otherwise cleaned plates on a vacuum rolling mill.

.

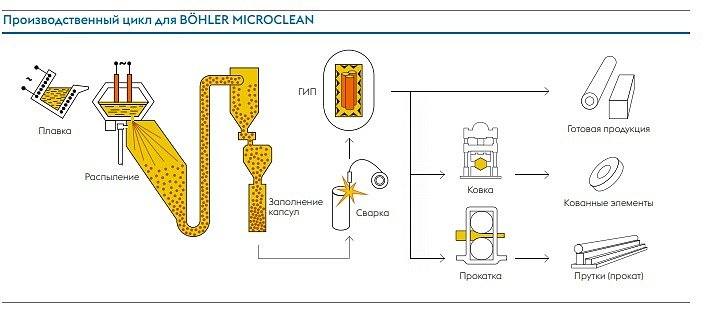

The vacuum method is also used in powder metallurgy. A sealed, oxygen-free capsule filled with wire, metal powder or mixtures is placed in an inert gas-filled chamber of a gas-stat. The capsule is heated to 1200-1400°C and the chamber is filled with gas, up to a pressure of approximately 1500 atmospheres. After the pressurized sintering of the composite material is complete, the sintered composite shell is mechanically removed and the cleaned composite is press forged or rolled through a rolling mill. Almost any type of damask can be produced by this method.

.

The advent of these technologies made it possible for large steel companies to produce damask in very large quantities. The largest of these companies was the Swedish Damasteel AB, which in 1996 received a patent for the production of powdered damask blanks. Damasteel’s production technology was “hot isostatic pressing”, which turns a rapidly hardening powder into a compact billet. Powders of two or more types of steel are placed in the center of a steel capsule in which a vacuum is created and hermetically sealed. The powders are sintered together under high pressure in a hot isostatic press. Pressing continues until the density reaches 100%. Damasteel produces two types of billets by powder metallurgy – bars with a layered concentric pattern and a multilayer package with parallel layers. The billets can then be used to create more complex patterns in the forging process.

.

The advantages of Damasteel steel are high corrosion resistance, predictable heat treatment regimes, pure chemical composition with minimal impurities, very good cutting properties when alloyed with vanadium. It is also important that the hardness of the metal after heat treatment reaches 63.5 HRC. With ordinary damask it is impossible to speak accurately about the hardness, it will be extremely heterogeneous throughout the blade after forging. Powdered damask solves this problem by creating a homogeneous structure. In addition to making knives, Damascus steel is also used to create a variety of jewelry and costume jewelry. Damasteel steel is also used to create items made with the Japanese mokume-gane technique.

.

Damasteel is based on RWL34 steel, a powdered, high-carbon steel additionally alloyed with molybdenum and vanadium, with medium corrosion resistance. It is produced by Damasteel AB itself. It has a good combination of cutting edge resistance, corrosion resistance and mechanical properties, and holds a thin cutting edge well. It has a large number of alloying elements, including manganese, molybdenum, vanadium, chromium and sulfur. With its high hardness, the steel is well machinable – ground and polished, it is excellent for blades of complex geometry and is considered one of the best steels for artistic etching. Several damask packages are produced with the use of this steel, the most popular among them are:

.

.

The DS93X package is a martensitic steel with a Damascus steel pattern. It consists of two different hardened knife steel grades. The light component is RWL34 powder steel and the dark component is RMS-27 carbon steel.

.

The Damacore DC18N package is also a martensitic steel. It contains three different alloys. The central core consists of N11X, an alloy steel with a high nitrogen content. The outer layers with the damask pattern consist of RWL34 and PMC27. The steel has high hardness after quenching and tempering.

.

Both packages have excellent corrosion resistance and high mechanical strength. These steels also have good ductility and are easy to grind and polish.

.

Thus, on the example of powdered damask, we see a harmonious combination of ancient technologies of production of beautiful and strong steel, with the most advanced technologies of powder processing.