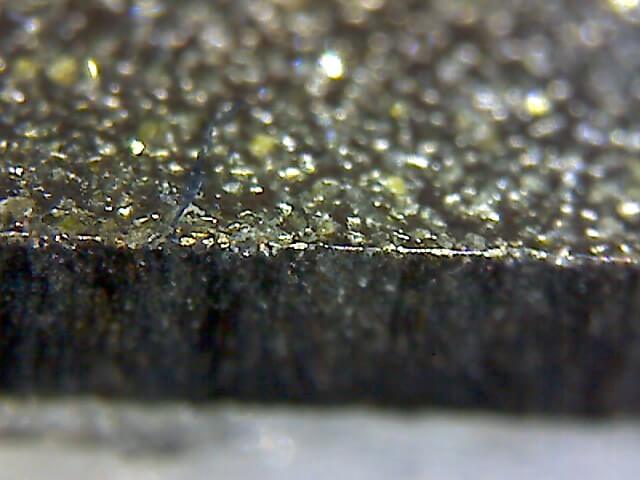

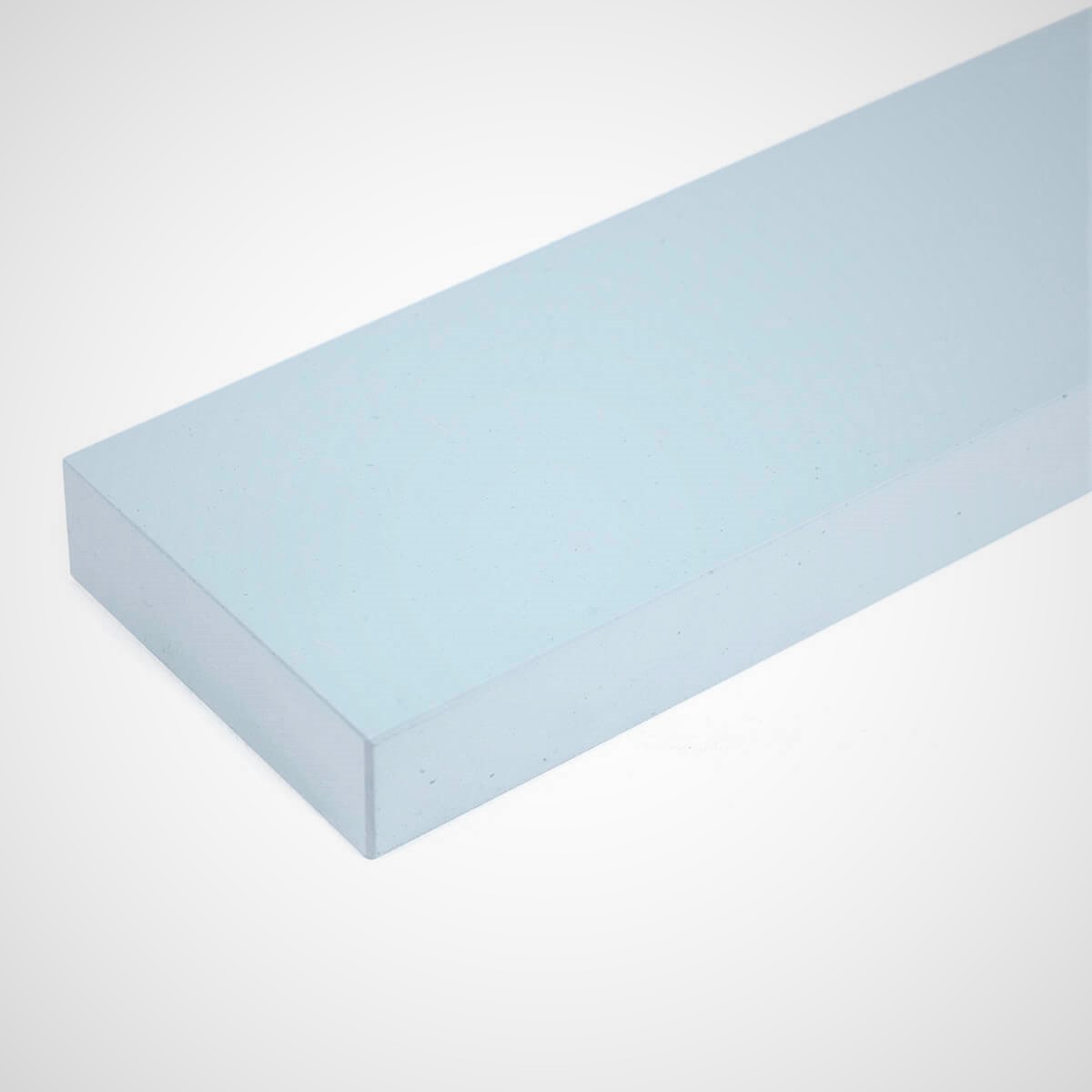

Silicon carbide (carborundum) is a binary inorganic chemical compound of silicon and carbon. The chemical formula is SiC. It is found in nature in the form of the mineral muassanite. Silicon carbide powder was first obtained in the laboratory in 1893. It is used as an abrasive, semiconductor, in microelectronics (in the powertrains of electric cars), and for imitating diamond inlays in jewelry.

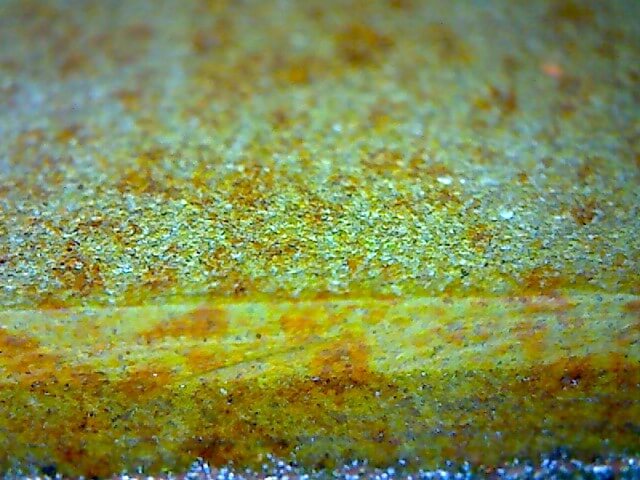

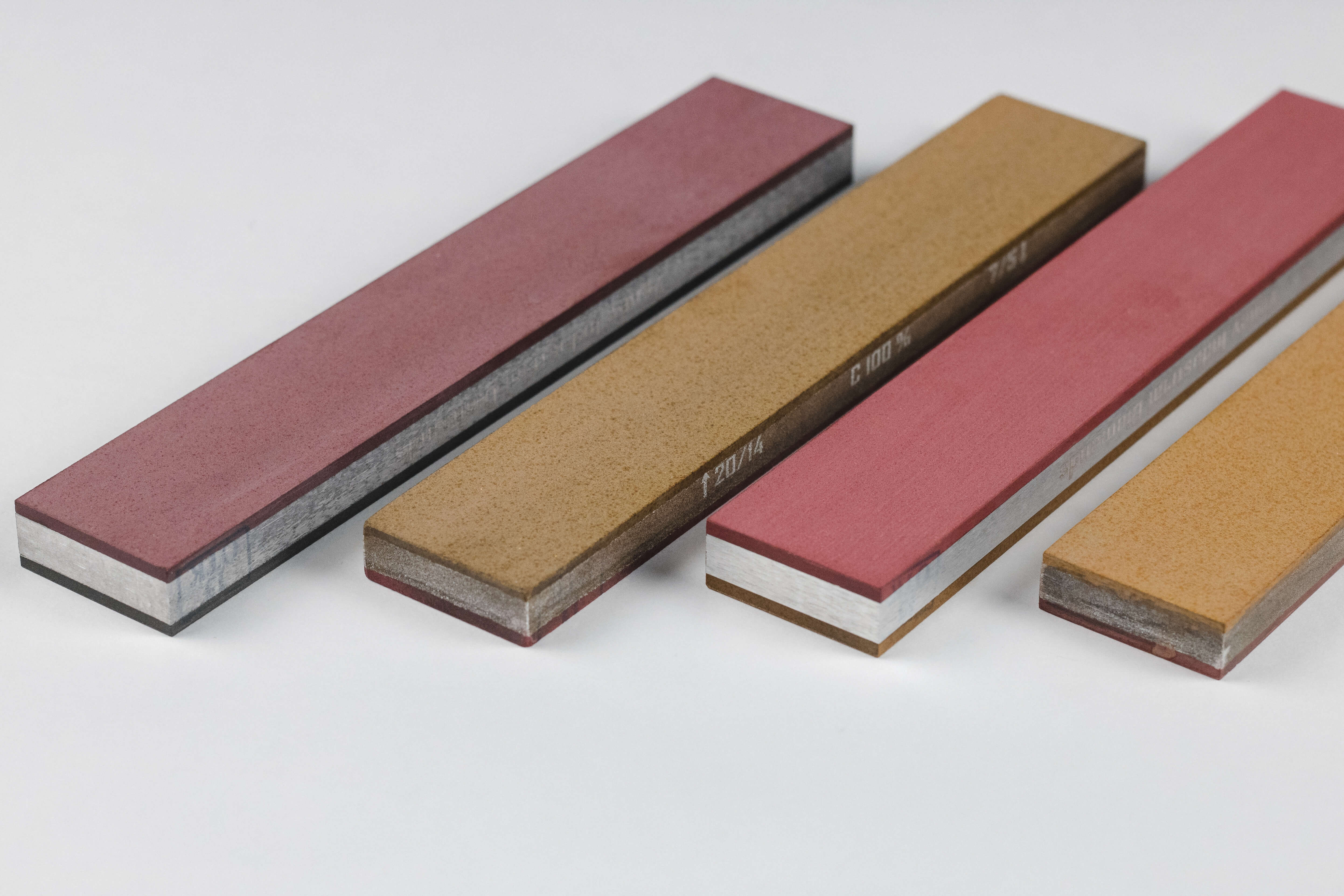

Silicon carbide of natural, mainly cosmic origin is a very rare element, so all silicon carbide available today is synthetically produced. Basically by sintering silica with carbon at high temperatures. Pure silicon carbide is colorless. Its shades of brown to black color are due to iron impurities. Finely ground silicon carbide turns into powder and it is in this form that it is used for dressing stones.

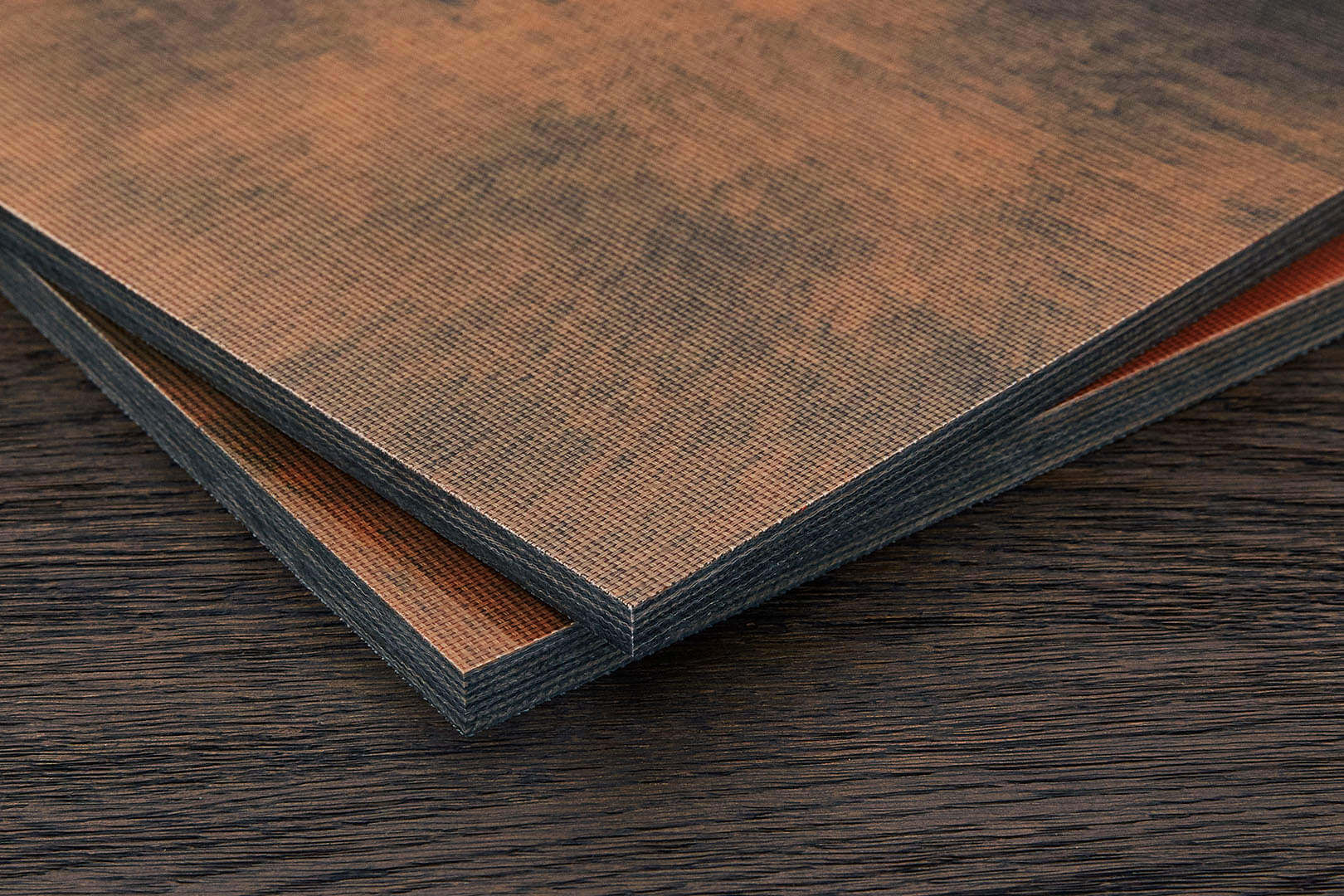

Silicon carbide powder is an abrasive material that is used to create an aqueous suspension when smoothing the surface of a sharpening stone. Due to its properties, it gives a uniform suspension of milky color, which is well retained between rubbing surfaces. It is used for work together with lappers.

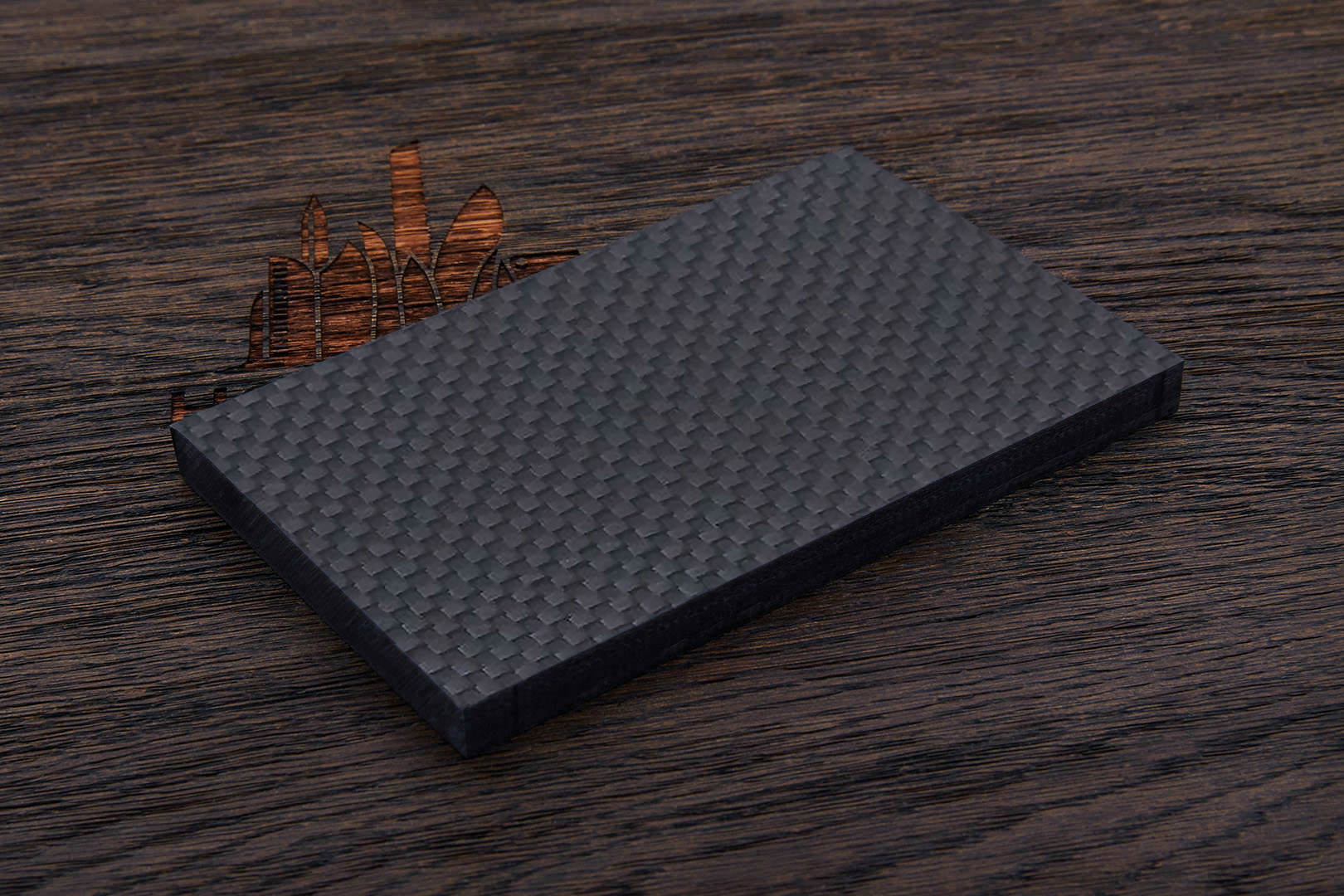

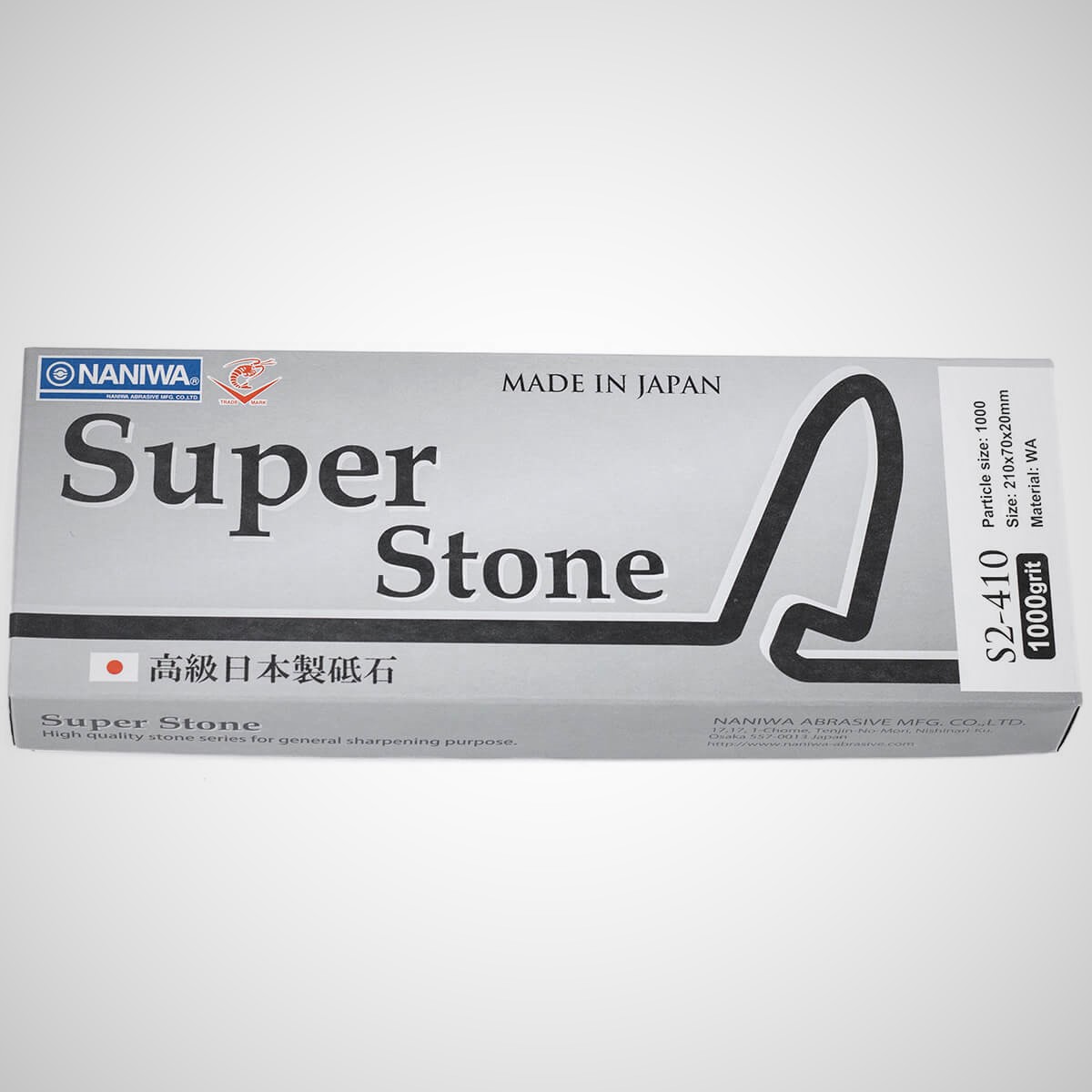

What is the purpose of leveling sharpening stones? Without leveling the plane of the stone, we cannot properly control the angle between the feed and the surface of the stone, this will result in a disturbed angle, blockage of the edge. In order to check the degree of wear of the stone surface, you can take a ruler and place it with its edge on the stone and place a light source behind it. If, having looked between the ruler and the stone we will see a gap, it means that the stone needs to be straightened on the working surface.

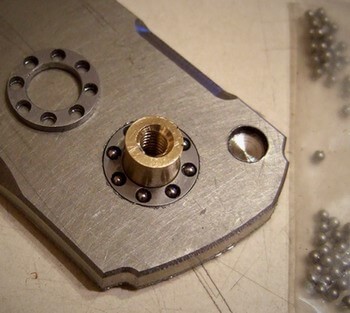

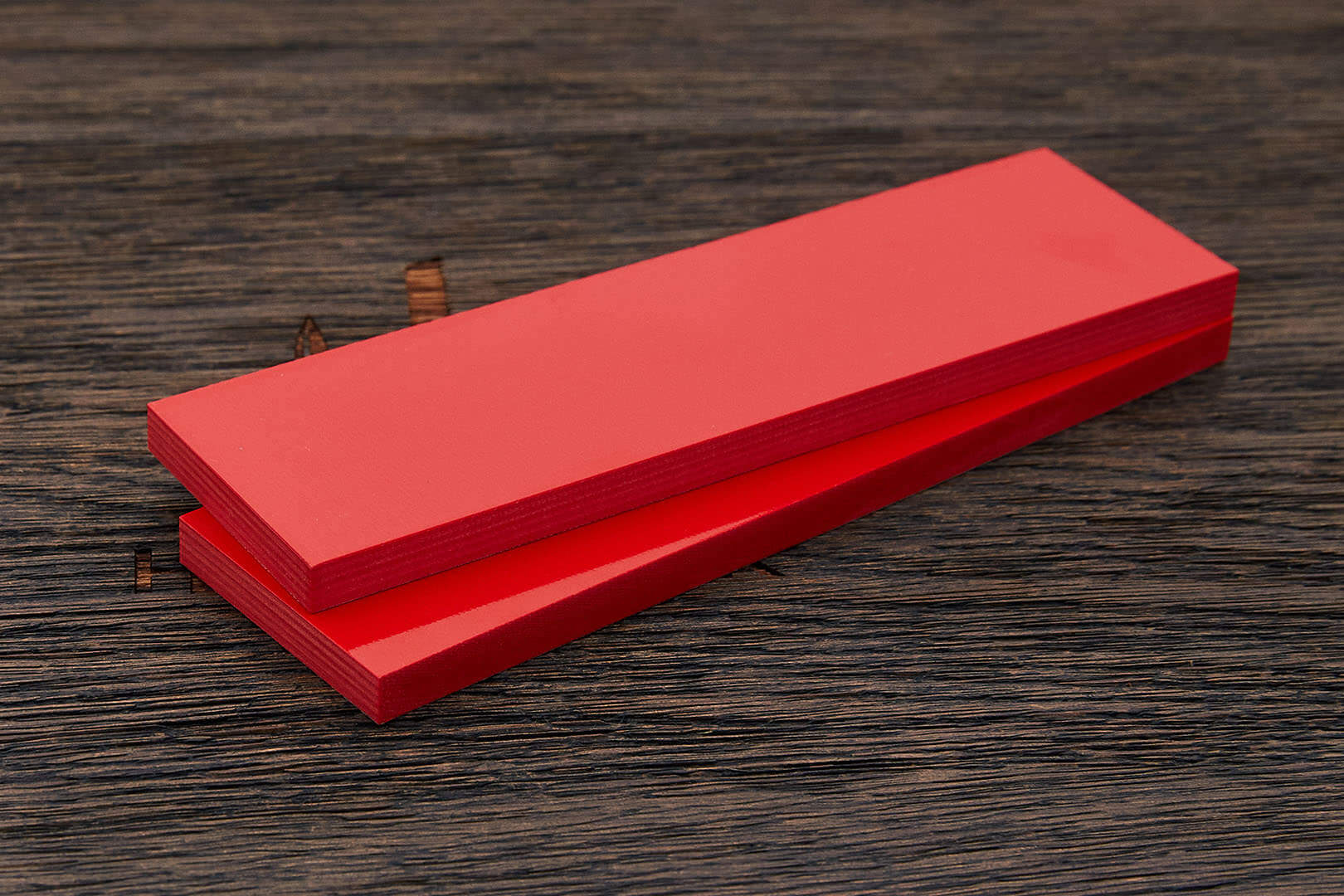

The most affordable way to level stones is by dressing on glass. For artificial stone, the size of the glass is preferably one and a half times the size of the stone. For natural stones, the size should be several times larger, as natural stones are harder and the glass will be seriously worn. It is very important that the glass is thick and will not sag.

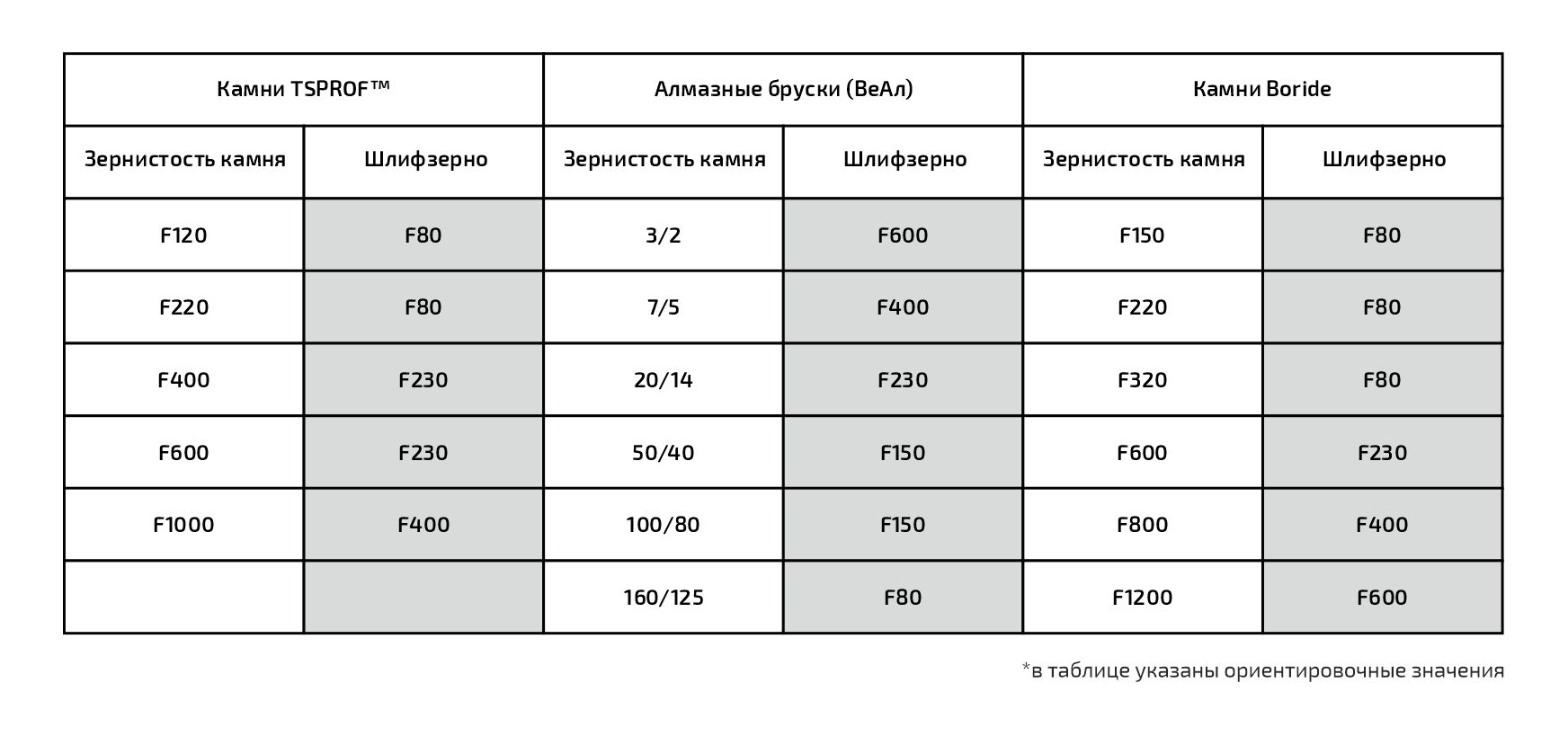

The main question that arises when preparing to level stones is what type of powder to use for a particular stone? A rule of thumb for this is that the powder grain should be 2-3 times the size of the stone grain.

For example, for Arkansas stones, this system might apply:

For Washita stone leveling, F120 silicon carbide powder is used.

For leveling Arkansas Translucent stone, F800-1200 powder is used.

For leveling Arkansas Black stone, F1200 powder is used.

However, these are only theoretical, each sharpening enthusiast must develop his own system in this matter and follow it.

The alignment technique used by most sharpeners is as follows: a pencil grid is applied to the stone, which must be completely rubbed out on a lapping stone with the powder applied. A simple pencil can be used. The grid should be applied to the stone wiped dry. For the leveling process, a small amount of powder is poured on the glass and water is added so that the glass is completely covered with a thin film of water. That is, when working, the water should not leave the edges of the glass. Then the stone is made movements, they are best to make a figure eight with two hands, and moving the stone from the left edge of the glass to the right and back. It is very important in such work do not forget to constantly add water, because if the suspension becomes too thick, it will lead to a piling of the surface of the stone. The work should be carried out until the mesh is completely gone. After that you can move to a finer grinder, or finish leveling. It is very important in the process of work to chamfer the bars, since their edges become very sharp and can damage the knife when sharpening. When using coarse powder, it should be remembered – you do not need to put a lot of pressure on the sharpening stone, otherwise, again, the surface may be bogged down. Leveling stones on silicon carbide is a meticulous, time-consuming job that requires patience and concentration.

This alignment on silicon carbide, is also used in what is called “stripping” or “shaking” the stones. The same movements as for leveling are used to remove the baked layer on the stone with which it comes from the factory. In the process, the grains of the synthetic stone are “opened”. This procedure is mandatory for stones, without it the stone’s efficiency will not be high.

It is also important not to forget that silicon carbide powder is a volatile substance, which can get into the respiratory tract of a person in dry form. It is therefore necessary to work with it carefully, use construction respirators and keep the workplace away from foodstuffs.